LEELA PHARMA MACHINERIES

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to LEELA PHARMA MACHINERIES

Rotary Bottle Washing Machine

With thorough industry knowledge, we are engaged in manufacturing, supplying and trading Rotary Bottle Washing Machine.

Rotary bottle washing machine is designed as per GMP Standard to wash containers of glass, plastic or other material.

Salient Features :

Provided with four separate stations for inside wash and one station for outside wash.

Washing sequences and positioning of washing stations can be interchanged as required for liquid oral and injectables.

A vary speed drive is provided for different output between 60 to 110 bottles per minute.

The specially designed cups are provided on the platform to accommodate any size of bottle from 60ml to 500ml

'GENEVA MECHANISM' eliminates carbon plate which avoids leakage and maintenance is minimized.

As the washing nozzles are stationary, the contamination of wash water is eliminated.

Bottle Filling Machine

Customers can avail Bottle Filling Machine form us as per the industry standards. Our product is used in beverage, foods and many more industries.

Semi – Automatic Machine ( Two, Four Head )

For accuracy to fill liquids into bottles, vials, cans etc. The unit is strong constructed and covered with s.s.304 sheet. The unit provide 3 different speed to give output : 1200 to 2000 Bottles/hr, Depend upon liquids, operator. The unit is driven by ½ H.P. Motor with suitable gear box . The two standard syringes are fitted on either side of the machine. Complete as per our standard

Automatic Liquid Filling Machine

We are manufacturing wide range of Automatic Liquid Filling Machines. The unit is having strong base to give trouble free operation. All S.S. cover with mirror polish. The basic unit consists of SS Conveyor belt with Extra D.C. Motor & speed regulator for conveyor speed, Bottle guide, Unique Co-Eccentric, Pre-gassing, Filling & Post-gassing SS 316 Nozzles. Easy Volume setting with Eccentric Screw. Filling assembly is diving type with drip proof nozzles. “ A NO VIAL NO FILL” Mechanism ensures smooth functioning of the machine. Vials stop & release through a fiber STAR PLATE WITH CLUTCH. Fiber star plate changes as per vial Dia. S.S. tray with screen is provided for keeping the bungs. Castor wheels & level bolts will be fitted with machine base. The machine is suitable for filling up 110 Ml. 4nos of 5ml to10ml S.S 316 Syringe will be fitted with machine. Machine is driven by 1 Hp. 3 phase, 440 Volts motor with suitable gear box & steep pulley. Output: 60 to 90vials/min.

Empty vials inspection is provided on the slat conveyor befor filling station. The machine is manufactured as per GMP Standared.

OPERATION:

Vials received on the SS Conveyor moves below the nozzles & centered correctly with the help of fiber star plate with clutch which also helps in presence of the vials. Syringes will draw correct vloume of liquid & delivered it through pipe to nozzles. During down word stroke will continuosly release the in let gas before during & after liquid filling. Vials after pre-gassing. Liquid filling & Post-gassing. Are tranferred through conveyor. Machine is complete.

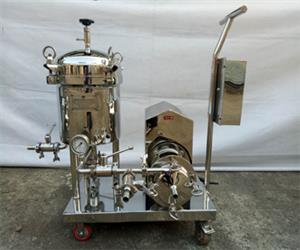

Sugar Syrup Making Machine

Description / Specification of Sugar Syrup Making Machine

We are involved in offering a wide range of Sugar Syrup Making Machine to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Sugar Syrup Making Machine. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.